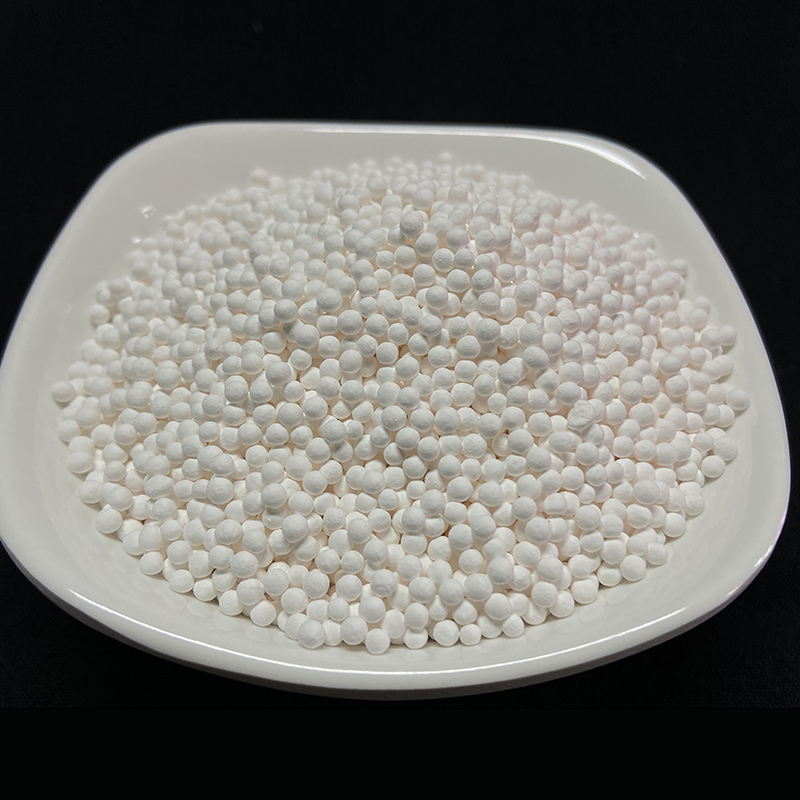

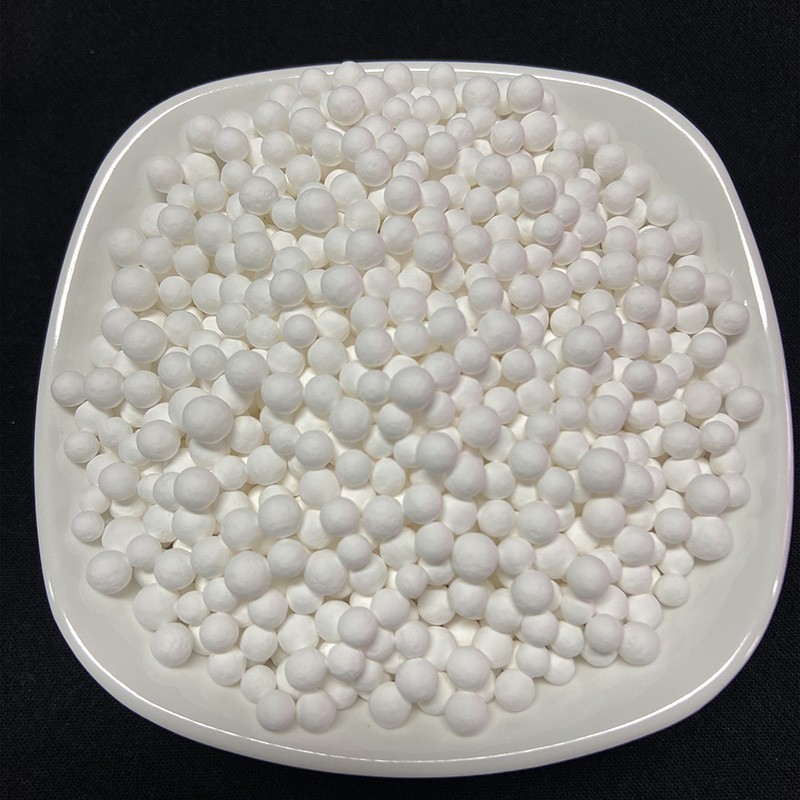

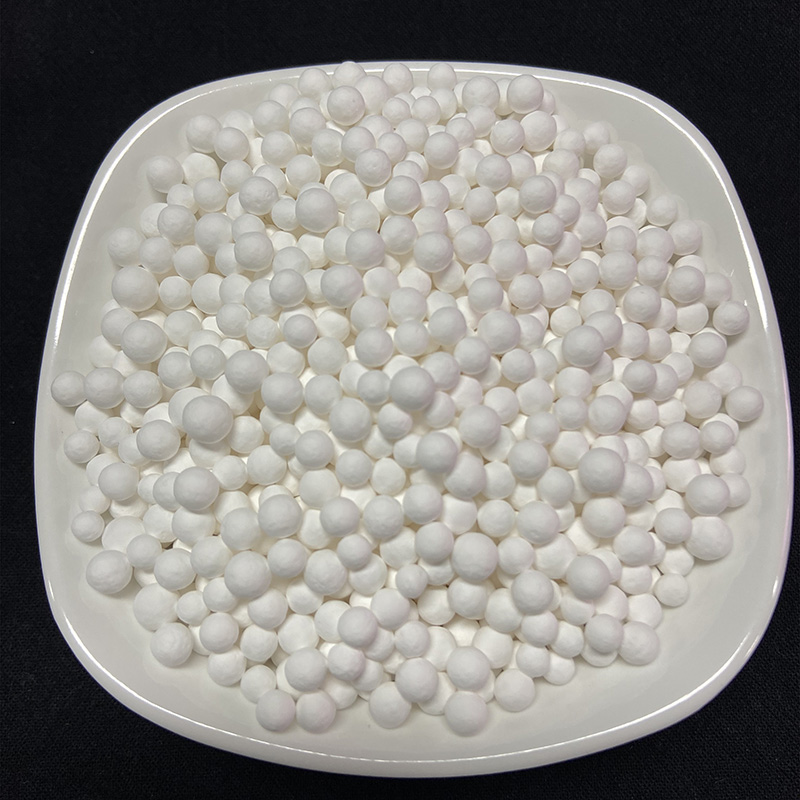

Alumina Keramik Filler High Alumina Inert Ball / 99% alumina bal keramik

Sipat Fisik Jeung Kimia Bola Keramik Inert

| Sipat fisik sareng kimia tina bal keramik inert | |||||||

| unsur | Al2O3% | 60 | 70 | 80 | 90 | 95 | 99 |

| Fe2O3% | ≤0.9 | ≤0.8 | ≤0.6 | ≤0.4 | ≤0.3 | ≤0.1 | |

| Komponén sésana bisa ditangtukeun ngaliwatan badami antara supplier jeung nu meuli lamun perlu. | |||||||

| nyerep cai,% | 3±1, Éta ogé bisa ditangtukeun ku badami antara supplier jeung nu meuli | ||||||

| proporsi, kg/m³ | 2.5-3.0 | 2.7-3.2 | 2.9-3.2 | ≥3.1 | ≥3.2 | ≥3.4 | |

| Kapadetan bulk, kg/m³ | 1400-1550 | 1400-1650 | 1500-1800 | 1700-1950 | 1800-1950 | ≥1900 | |

| Lebu, rengat atawa peupeus | Hiji kantong kirang ti 5% | ||||||

| Ukuran simpangan | Lapisan seragam, babandingan diaméter anu panggedéna ka pangleutikna tina lapisan keramik henteu langkung ti 1,2 | ||||||

| Toleransi diménsi | ≤10mm | ± 1.0 | |||||

| 11-25 mm | ± 1,5 | ||||||

| 26-50 mm | ± 2.0 | ||||||

| ≥50mm | ± 3.0 | ||||||

| Kakuatan ragrag bébas | Laju Lossless ≥99% | ||||||

| Kakuatan compressive | φ3 | ≥250 | ≥300 | ≥350 | ≥400 | ≥500 | ≥500 |

| φ6 | ≥800 | ≥1000 | ≥1000 | ≥1200 | ≥1500 | ≥1500 | |

| φ8 | ≥1500 | ≥1600 | ≥1800 | ≥2000 | ≥2500 | ≥2500 | |

| φ10 | ≥2000 | ≥2500 | ≥2800 | ≥3000 | ≥3500 | ≥3500 | |

| φ13 | ≥3000 | ≥3000 | ≥3500 | ≥4000 | ≥5000 | ≥5000 | |

| φ16 | ≥3500 | ≥4000 | ≥4500 | ≥5000 | ≥6000 | ≥7000 | |

| φ20 | ≥6000 | ≥6000 | ≥7000 | ≥8000 | ≥10000 | ≥12000 | |

| φ25 | ≥7000 | ≥7000 | ≥8000 | ≥10000 | ≥15000 | ≥17000 | |

| φ30 | ≥8000 | ≥9000 | ≥10000 | ≥12000 | ≥17000 | ≥19000 | |

| φ38 | ≥10000 | ≥12000 | ≥13000 | ≥15000 | ≥20000 | ≥22000 | |

| φ50 | ≥12000 | ≥14000 | ≥16000 | ≥18000 | ≥22000 | ≥26000 | |

| φ75 | ≥16000 | ≥18000 | ≥20000 | ≥22000 | ≥25000 | ≥30000 | |

| 50-75 | 55-75 | 60-80 | ≥80 | ≥82 | ≥85 | ||

| Laju ngagem% | ≤2 | ≤1 | |||||

| kaleyuran asam % | ≤6 | ||||||

| alkalinitas % | ≥77 | ≥85 | ≥90 | ≥92 | ≥95 | ≥97 | |

| Refractoriness, ℃ | ≥400 | ≥500 | ≥700 | ≥1000 | ≥1000 | ≥1000 | |

| Tahan kana bédana tekanan ngadadak | Laju non-destructive ≥ 99%, euweuh parobahan kakuatan compressive sarta tekanan sanggeus robah ngadadak kirang ti 25% | ||||||

| Tahan kana parobahan suhu anu ngadadak | Laju Lossless≥99% | ||||||

| Bungkusan | Bungkusan kendang beusi | Dipak dina drum beusi, disegel ku kandel PP atawa kantong plastik pe | |||||

| Bungkusan kantong anyaman | Sadia dina kantong anyaman anu kuat sareng tahan UV | ||||||

| Catetan: Data dénsitas bulk kanggo rujukan wungkul, sanés janten dasar pikeun ditampa. | |||||||

Catetan sejen: Tempo Table 5 Pikeun nyerep cai 99 Filler Balls

| 99 Ngeusian Ball Cai Nyerep | ||

| 99 pangeusi | diaméterna | diaméterna |

| roll ngabentuk | φ<25 mm | <5% |

| Mesin pencét ngabentuk | φ> 25 mm | <10% |

99,5% Indikator Téknis

| Al2O3 | ≥99% |

| SiO2 | ≤0,14% |

| Fe2O3 | ≤0,04% |

| CaO + MgO | ≤0,03% |

| TiO2 | ≤0,06% |

| Na2O | ≤0,1% |

| K2O | ≤0,1% |

Indéks Fisik Ball Filler Kimia

| SYARAT | INDEKS |

| lemesna beban (yb/t370-1995) | Deformasi dina tekanan 0.2mpa kurang ti 0.6% |

| Résistansi shock termal (yb/t376.2-1995) | 1200 ° C turun ka 600 ° C. 10 kali tanpa retakan permukaan |

| Parobahan garis reburn (gb/t3997.1-1998) | 1400 ℃ pikeun 12 jam, nilai maksimum nyaéta 0,25%, nilai rata-rata kirang ti 0,20% |

| Dénsitas bulk (gb/t2997-2000) | 3,2-3,50 g / cm3 |

| kakuatan crushing | Minuhan langkung ti 230 kg/cm2 |

| Porosity semu | 12-18% |

| Kapadetan bulk | 2.1-2.3g/cm3 |

Kimia Bungkusan Ball Packing

1) packing biasa: poliétilén anyaman kantong kalawan beurat net 25kg, tambah Usuk

2) Bungkusan kendang baja: bungkusan kendang baja 100L, pallets tiasa ditambah